BIWFix Pro – Precision Fixture Design for Automotive BIW

In automotive manufacturing, Body-in-White (BIW) fixture design plays a critical role in ensuring dimensional accuracy, process consistency, and overall assembly quality. However, maintaining compliance with multiple OEM standards, performing repetitive quality checks, and coordinating between design and manufacturing can be tedious and error-prone.

BIWFix Pro simplifies this process with a unified fixture design and quality control automation platform tailored for BIW engineering teams, integrators, and OEMs.

Developed for Siemens NX CAD, BIWFix Pro enables automated fixture validation covering everything from NC contact and hole alignment checks to assembly clearances, stock size validation, and drafting QC.

With built-in support for GM, Daimler, and Stellantis fixture requirements, BIWFix Pro helps teams design, validate, and deliver compliant BIW fixtures faster, with fewer iterations and higher confidence.

Why Choose BIWFix Pro?

BIWFix Pro is a specialized fixture design and quality automation tool designed specifically for the automotive Body-in-White (BIW) domain. It integrates advanced modeling and drafting validation features into Siemens NX, ensuring fixture designs meet OEM-specific requirements and internal quality standards. The software automates repetitive and error-prone tasks such as NC contact verification, hole attribute validation, stock material checks, and assembly interference detection.

With built-in quality assurance modules, BIWFix Pro improves design accuracy, minimizes manual rework, and accelerates fixture delivery timelines.

OEM-Centric Compliance

Built with direct reference to GM, Daimler, and Stellantis fixture standards, ensuring seamless alignment with OEM deliverables.

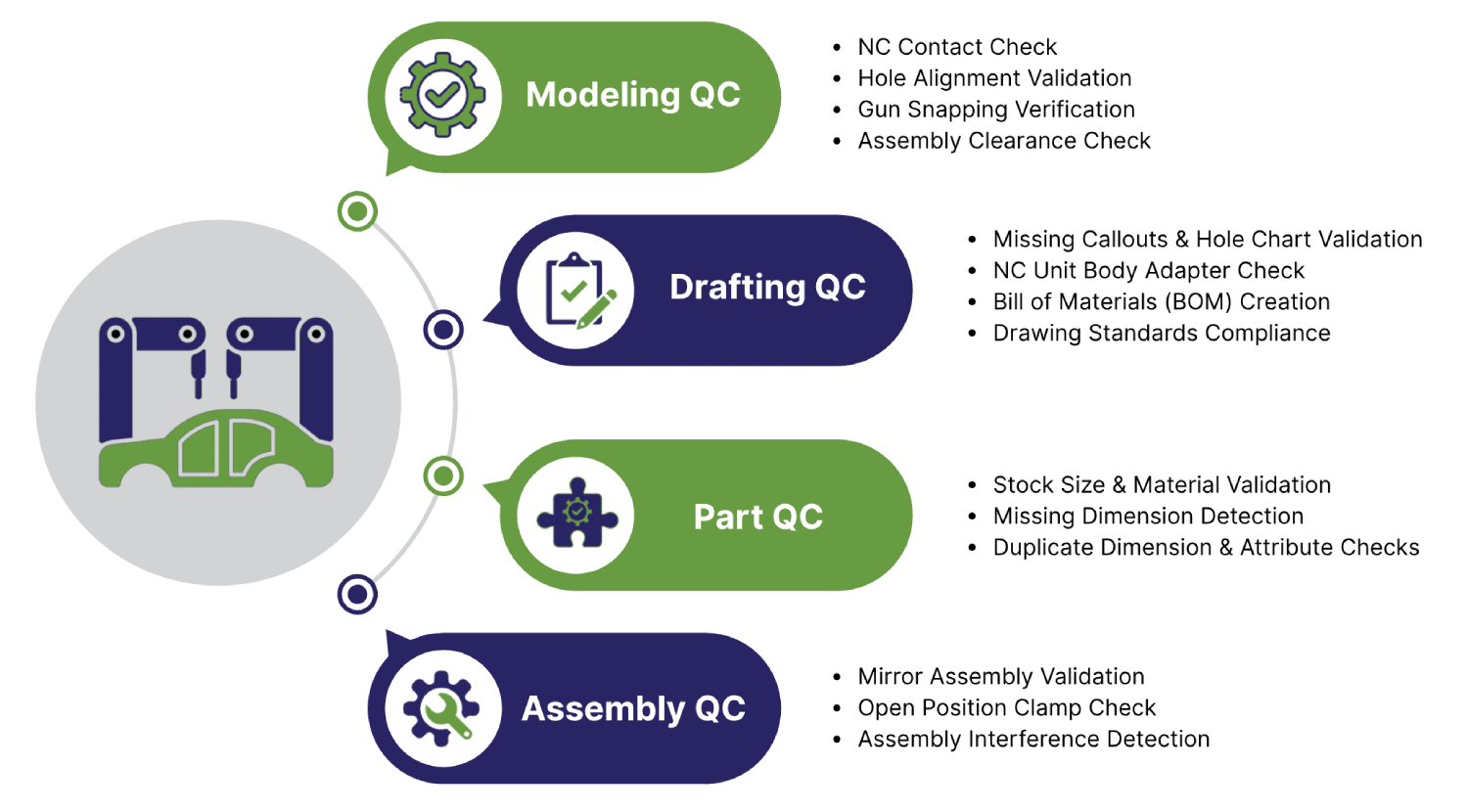

End-to-End QC Automation

Automates checks from early modeling stages to final drafting deliverables, maintaining data integrity throughout the fixture design process.

Streamlined Workflows

Performs automated validation of hole alignment, material sizing, stock dimensions, and NC contact accuracy significantly improving productivity.

Improved Collaboration

Export deliverables like DXF files, BOMs, and detailed reports for smooth collaboration between design, assembly, and manufacturing teams.

How It Works

1. Start or Import BIW Fixture Design

Open or import BIW fixture models directly in Siemens NX CAD.

2. Run Automated NC Contact Checks

Validate NC contact conditions and hole attributes with built-in OEM-based validation logic.

3. Perform Assembly & Part QC

Execute checks for hole positions, material sizing, assembly clearance, and weight management to ensure fixture accuracy.

4. Generate Quality Reports & Drafting Outputs

Create detailed compliance reports, hole charts, and drafting deliverables aligned with automotive standards.

5. Review & Finalize Deliverables

Conduct multidisciplinary reviews with clear BIWFix Pro reports for fast sign-off and customer validation.

Value Proposition

BIWFix Pro empowers automotive design teams to accelerate fixture delivery while ensuring total compliance with OEM standards.

By automating repetitive QC checks, validating design integrity, and standardizing outputs, it minimizes rework and costly late-stage corrections.

💡 Key benefits include:

Reduced rework costs through early issue detection.

Confidence in OEM-specific compliance and data integrity.

Faster time-to-market via workflow automation.

Unified modeling and drafting QC in a single platform.

Comprehensive, transparent reporting for design reviews and audits.

🏭 Industries Benefiting

Automotive OEMs & Suppliers

focused on BIW assembly design and validation.

Heavy Vehicle & Commercial Manufacturers

Leveraging BIW processes.

Tooling & Fixture Design Firms

providing BIW solutions for multiple OEMs.

Engineering Service Providers

supporting automotive BIW programs.

🌟 Target Users

- Automotive BIW fixture design engineers : working on OEM-specific projects.

- Fixture integration specialists : preparing designs for manufacturing.

- OEM QC and design release teams : responsible for validation and compliance.

- Tier-1 & Tier-2 automotive suppliers : engaged in BIW manufacturing and assembly.

👉 Automate, Validate, and Deliver BIW Fixtures with Confidence

Frequently Asked Questions (FAQs)

Which CAD platforms does BIWFix Pro support?

Does it support BIW standards for multiple OEMs?

Can it automate both modeling and drafting QC checks?

How does BIWFix Pro improve BIW fixture quality and delivery?

Can it generate reports for internal and customer review?

Explore real-world Toolkit Solutions showcasing how NX CAD Tools deliver automated precision validation, streamline workflows, and enhance engineering outcomes with unmatched efficiency

BIWFix Pro