ToolReach Validator – Ensure Flawless Accessibility for Spanners, Weld Guns, Torx Heads & Other Automotive Assembly Tools

In modern automotive and manufacturing environments, even a perfectly designed product can face costly assembly issues if tools can’t reach critical fastening or welding points.

Accessibility gaps, interference, or poor ergonomic design often surface too late during production causing rework, downtime, or safety risks.

ToolReach Validator eliminates these uncertainties early in the design phase.

It simulates the accessibility of assembly tools such as spanners, weld guns, Torx drivers, and pneumatic or electric screwdrivers within complex 3D assemblies. By analyzing tool reach, motion dynamics, and ergonomic comfort, it ensures engineers design with real-world assembly feasibility in mind.

Seamlessly integrated with Siemens NX, Solid Edge, and Autodesk Inventor, ToolReach Validator brings real-time, simulation-based validation directly into your CAD environment.

The result: safer, faster, and more efficient assembly processes that align with Design for Assembly (DFA) and ergonomic standards.

Why Choose ToolReach Validator?

ToolReach Validator is an advanced simulation and validation solution designed to evaluate and optimize tool accessibility, reachability, and ergonomic compliance directly within CAD assemblies. By digitally replicating the geometry, motion, and dynamics of real-world tools, it helps manufacturing and design teams detect interference, blind spots, and operator reach issues early. The software empowers engineers to simulate, visualize, and document how actual tools manual or powered interact with products during assembly.

This ensures every tightening, welding, or fastening operation is physically feasible, ergonomically safe, and production-ready. Built for high-precision industries such as automotive, aerospace, and machinery, ToolReach Validator serves as an essential bridge between design intent and manufacturing execution.

Multi-Tool Simulation

Supports all common automotive and industrial tools, including manual/powered spanners, weld guns, Torx heads, and pneumatic tools.

Detailed Tool Geometry

Uses realistic 3D models of tools for accurate spatial simulation and access evaluation.

Dynamic Reach & Collision Analysis

Validates tool movement paths and articulations, identifying any geometric interference or accessibility constraint.

Ergonomic Comfort Metrics

Assesses operator reach, angles, and posture to ensure ergonomic compliance and minimize injury risk.

Custom Tool Libraries

Allows easy extension of tool databases add, modify, or replace tool models to match shop-floor inventories.

Assembly Integration

Fully compatible with Siemens NX, Solid Edge, and Autodesk Inventor. Supports imported assemblies for cross-platform projects.

Exportable Reports

Generates detailed accessibility and ergonomic evaluation reports, complete with visual highlights and metrics for documentation and review.

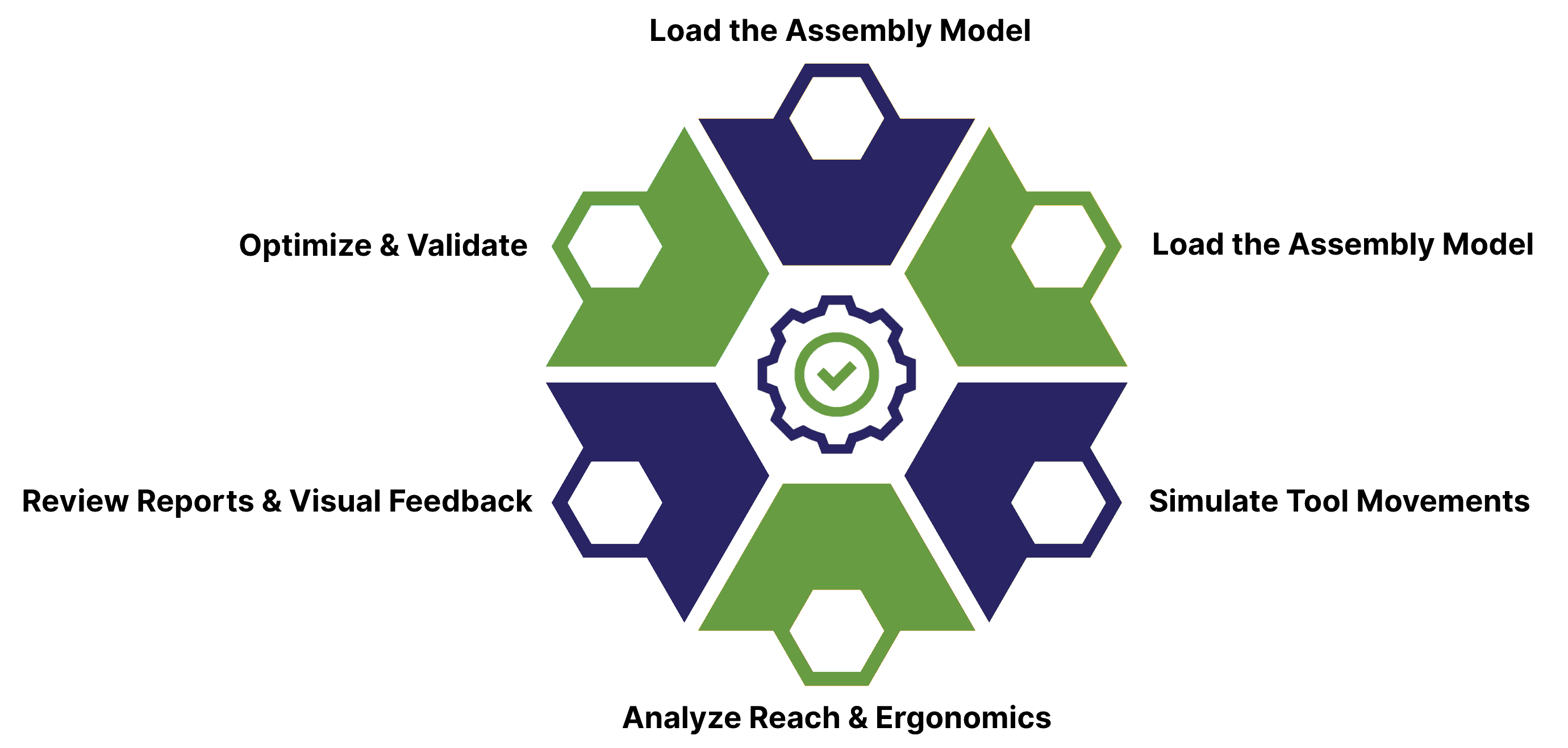

ToolReach Validator Working Process

How It Works

1. Load the Assembly Model

Import your 3D product assembly into Siemens NX, Solid Edge, or Autodesk Inventor.

2. Select the Tooling Suite

Choose from predefined tool libraries or load your own custom tool models—such as spanners, weld guns, or drivers.

3. Simulate Tool Movements

Articulate the selected tool through its range of motion within the CAD environment, simulating realistic access paths.

4. Analyze Reach & Ergonomics

ToolReach Validator automatically detects interference, checks reachability, and evaluates operator comfort zones based on ergonomic standards.

5. Review Reports & Visual Feedback

Interactive visuals highlight problem areas, while detailed reports summarize reach metrics, clearance data, and ergonomic findings.

6. Optimize & Validate

Make informed design modifications, re-run simulations, and confirm that all tools can reach and operate effectively before final design release.

Why ToolReach Validator

ToolReach Validator ensures that every design you release is manufacturable, accessible, and ergonomically safe.

By digitally simulating tool access before production, it eliminates costly surprises and time-consuming rework on the factory floor.

💡 Designer & Engineer Benefits

Accelerate design-to-manufacturing timelines

with early tool reach validation.

Prevent costly production delays

caused by inaccessible tooling or interference.

Enhance ergonomics

and operator safety using built-in comfort metrics.

Improve collaboration

between design, manufacturing, and ergonomics teams with clear, shareable visual data.

Support compliance

with global occupational health and safety standards.

Adapt instantly

to new assembly sequences or tooling configurations with re-simulation capabilities.

This tool helps engineers:

Detect accessibility and ergonomic issues early.

Shorten DFA review cycles.

Achieve faster production readiness.

Support continuous improvement in safety and efficiency.

In short, ToolReach Validator transforms assembly planning from reactive to proactive bridging the gap between digital design and real-world manufacturability.

🌟 Use Cases of ToolReach Validator

- Automotive Tooling & Fixture Engineers : validating tool paths and access.

- Assembly Process Planners : optimizing design-for-assembly readiness.

- Manufacturing & Ergonomics Specialists : evaluating operator comfort and reach zones.

- QA & Production Engineers : conducting pre-production DFA validation and documentation.

👉 Ensure Every Tool Fits Before It Reaches the Shop Floor

Frequently Asked Questions (FAQs)

Which assembly tools can ToolReach Validator simulate?

How does the tool evaluate ergonomic risks?

What CAD systems does ToolReach Validator integrate with?

Can we add our own tools?

Does it generate reports for documentation?

Explore real-world Toolkit Solutions showcasing how NX CAD Tools deliver automated precision validation, streamline workflows, and enhance engineering outcomes with unmatched efficiency

ToolReach Validator