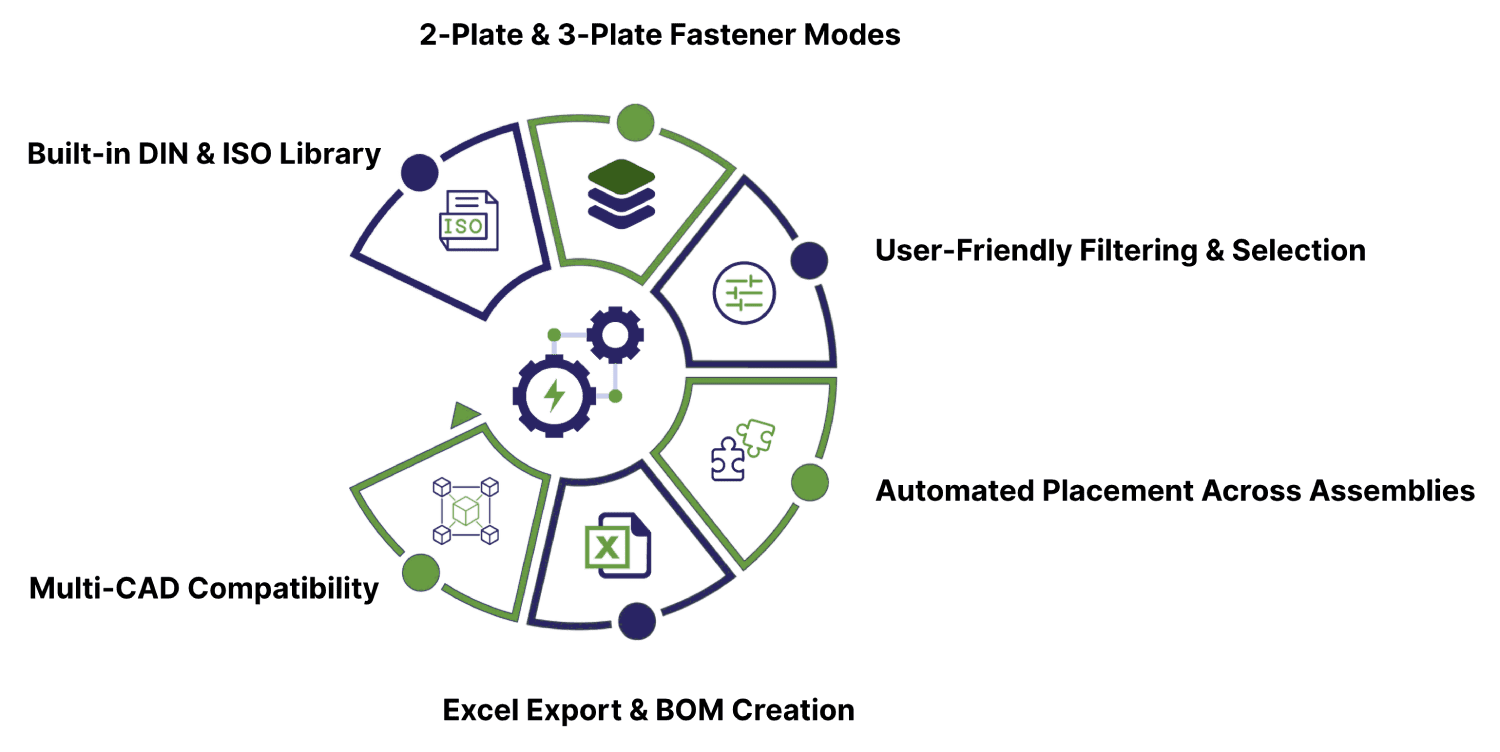

FastenMate Pro – Smart Fastener Assembly for Plates and More

FastenMate Pro revolutionizes how design teams handle fastener assemblies by automating hardware placement, validation, and documentation across multiple CAD platforms.

Traditionally, selecting and assembling correct fasteners for multi-plate configurations involves tedious manual work, catalog lookup, and documentation. FastenMate Pro eliminates all that offering standards-based, automated fastener population for 2-plate, 3-plate, and multi-plate assemblies with instant Excel and BOM generation.

Native to Siemens NX, Solid Edge, and Autodesk Inventor, the tool ensures accurate, compliant, and fully documented assemblies that meet both DIN/ISO standards and custom company specifications. It’s adaptable, efficient, and scalable for enterprises managing large mechanical design libraries.

Why Choose FastenMate Pro?

FastenMate Pro transforms a traditionally repetitive and error-prone design step into a fully automated, standards-compliant process that improves both speed and quality.

Built-in DIN & ISO Library

Access preloaded industry-standard fasteners or add custom ones, ensuring your assemblies always use approved hardware.

2-Plate & 3-Plate Fastener Modes

Automatically detect, configure, and place fasteners for 2-plate, 3-plate, or multi-plate joins ensuring correct stack order and length.

User-Friendly Filtering & Selection

Quickly locate fasteners by size, type, standard, or specification with smart filters and search menus.

Automated Placement Across Assemblies

Select plates, define mode, and let FastenMate Pro instantly handle fastener placement and documentation across all joints.

Excel Export & BOM Creation

Automatically generate a comprehensive Bill of Materials (BOM) and Excel reports for QA, procurement, and customer documentation.

Multi-CAD Compatibility

Works natively with Siemens NX, Solid Edge, and Inventor with flexible pathways for future CAD integrations.

Key Features of FastenMate Pro

How It Works

1. Launch FastenMate Pro

Open your assembly in Siemens NX, Solid Edge, or Inventor, and start the FastenMate Pro interface.

2. Choose Fastener Mode

Select between 2-plate, 3-plate, or custom multi-plate configuration modes.

3. Select Fastener Type

Pick from built-in DIN, ISO, or custom fastener libraries with filtering options for standards, sizes, or part types.

4. Place Automatically & Export Results

Run automated placement, generate an Excel summary/BOM, and finalize your design documentation—all in one workflow.

Value Proposition

FastenMate Pro transforms a traditionally repetitive and error-prone design step into a fully automated, standards-compliant process that improves both speed and quality.

💡 Key benefits include:

Accelerate Product Development

Populate fasteners across complex assemblies in seconds reducing design cycle time and manual revision needs.

Ensure Standards Compliance

Every assembly uses approved DIN/ISO or company-specific fasteners, guaranteeing precision and traceability.

Eliminate Guesswork

Automatically calculates correct fastener stacks, lengths, and types—no catalog lookups or manual fit checks required.

Seamless Documentation

Excel and BOM exports ensure smooth collaboration between design, procurement, and manufacturing.

Adaptable & Future-Ready

Add new fastener standards, custom part types, and CAD platforms as your organization grows.

Cross-Platform Advantage

Maintain consistency across NX, Solid Edge, and Inventor, ensuring all teams use unified hardware data regardless of CAD system.

🏭 Industries Benefiting from FastenMate Pro

Automotive & Transportation

Streamline vehicle component fastener design with OEM-level precision.

Aerospace & Defense

Meet stringent documentation and hardware traceability requirements.

Industrial Machinery & Equipment

Simplify large assembly fastener management and reporting.

Consumer Electronics & Appliances

Ensure precise fit and standardized fasteners in compact assemblies.

Heavy Equipment & Construction

Handle multi-plate configurations with large fasteners easily.

Energy & Utilities

Standardize hardware in high-load and structural equipment designs.

Medical Device Manufacturing

Maintain documentation and compliance for regulated hardware assemblies.

💡 Designer Benefits

- Assemble multi-plate joints in minutes with precise, standards-driven fasteners.

- Maintain DIN/ISO and customer-specific compliance across every project.

- Avoid manual stack calculations and eliminate assembly errors.

- Auto-generate accurate BOMs for purchasing and manufacturing teams.

- Save hours of repetitive work while improving overall design quality and consistency.

👉 Automate Fastener Assembly with Confidence

Frequently Asked Questions (FAQs)

Does FastenMate Pro support both 2-plate and 3-plate configurations?

What fastener standards are included?

Is FastenMate Pro expandable to other CAD platforms?

How does it help designers save time?

Explore real-world Toolkit Solutions showcasing how NX CAD Tools deliver automated precision validation, streamline workflows, and enhance engineering outcomes with unmatched efficiency

FastenMate Pro